PROMOSOLV COAT UT10

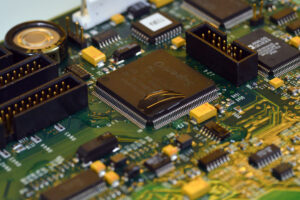

High-Performance Carrier Solvent for Ultra-Thin Coatings

- Ultra-thin hydrophobic & oleophobic coating

- Dipping & spray process

- Easy & fast process

PROMOSOLV COAT UT10

A transparent hydrophobic and oleophobic ultra-thin coating to protect electronics and other surfaces against moisture, corrosion and other environmental conditions that could jeopardize the reliability of the device or surface. Adheres well to a wide variety of material substrates as plastic, glass, metal and ceramic.

PROPERTIES

| SOLID CONTENT (WEIGHT %) | FILM THICKNESS |

|---|---|

| 0.2% | Dipping: <0,01 microns / Spray: not applicable |

| 2% | Dipping: 0,1–0,2 microns / Spray: typical 2 microns |

| 4% | Dipping: 0,2–0,4 microns / Spray: typical 4 microns |

| 8% | Dipping: 0,8–1 microns / Spray: not applicable |

LIQUID PROPERTIES

| CHARACTERISTICS | VALUES |

|---|---|

| Chemical nature | Fluoropolymer |

| Appearance | Clear to slightly cloudy |

| Density (g/cm³) at 20°C | 1,4 |

| Solvent type | Hydrofluoroether |

| Solvent product name | DILUENT 10 |

| Solvent Boiling point | 61-76°C / 142-169°F |

| Flash point | None |

| Viscosity (cSt) | ~1 |

| Surface tension (mN/m or dynes/cm) | 13,6 |

FILM PROPERTIES

| CHARACTERISTICS | VALUES |

|---|---|

| Appearance | Clear, colourless |

| Surface energy (dynes/cm) | 5–10 |

| Contact angle (ASTM D7334-08) | 120° water / 80° oil |

| Heat stability | 150°C continuous / 250°C one hour |

| Solder-through repairability | Yes |

| Solvent and chemical resistance | Excellent |

| Refractive index | ~1,35 |

| Tg (glass transition temperature) | 75°C |

| Dielectric strength | 2500 V/mil (2500 V/25μm) |

| Dielectric constant | 2,25 @100 KHz |

| Dissipation factor | 0,016 @100 KHz |

| Volume resistivity | 4,5×10¹⁵ Ω·cm |

| Non flammability certificates | UL94 V-0 / NF EN 60695-11-10 |

PROMOSOLV COAT UT10 is currently available at 2% and 4% solid content. A higher solid content will increase the coating thickness.

PROMOSOLV COAT UT10 can be considered as a replacement for 3M Novec 1700, which is scheduled to be phased out voluntarily by end 2025. More info on the announcement of 3M on the phase out of Novec products, click this link.

PERFORMANCE

- Provides exceptional repellence of all kinds of liquids.

- Fast drying at room temperature ( <1 min)

COST

- Substantial cost reduction due to small amount of product needed and simplicity of process.

- PCB masking is not required, saving on preparation time.

HSE

- No CMR substances

- Low environmental impact & very low VOC

- Non flammable

PROCESS EXAMPLES

The best process will depend on factors such as operating conditions, equipment, time and the cleanliness of the parts. Our team is ready to advise you.

Dip coating

- Dipping process recommended / spray application possible (especially for selective deposition)

- Typical coating thickness is about 0.2 microns

- Recommended to apply on cleaned and dried surfaces

- Touch dry within less than a minute / No thermal or UV cure required