ECOREL FREE LT 140-17A

Low temperature solder paste

- Sn42bi57.6ag0.4 solder paste

- Dispensing process

- Low melting point

ECOREL FREE LT 140-17A

Is a no clean dispensing solder paste combining the metallurgical properties and benefits of a low melting point alloy with high performance chemistry of the ECOREL™ flux chemistries, assuring that the assembled electronics can reach their best reliability. Low melting point solder pastes are recommended for thermal sensitive components such as LED’s, MEMS, CMOS and flexible circuits.

The paste has easily cleanable flux residue while having a melting point of around 140°C. Compared to state-of-the art low melting point alloy like SnBi, ECOREL FREE LT 140-17A achieves better wetting and solder joint strength due to the presence of silver.

| SPECIFICATIONS | ECOREL FREE LT 140-17A |

|---|---|

| Alloy | Sn42Bi57,6Ag0,4 |

| Melting point (°C/°F) | 140°C / 284°F |

| Metal content (%) | 87.5 – 88.5 |

| Post reflow residues | Approximately 6-7% by w/w |

| Halogen content (%) | 0.10-0.12 |

| Powder size | 25-45 microns / Type 3 |

| Viscosity* (Pa.s 20°C) | 400-550 |

*The equipment used is Brookfield RVT, Helipath T Mobile – 5 rpm

| CHARACTERISTICS | VALUES | METHOD |

|---|---|---|

| Flux Classification |

ROM1 112 |

ANSI/J-STD-004 ISO 9454 |

| Copper mirror | Pass | ANSI/J-STD-004 |

| Copper corrosion | Pass | ANSI/J-STD-004 |

| SIR (IPC) after cleaning After 21 days 85°C – 85 % RH – 50 Volts 20°C – 65 % RH |

Pass

> 1010 |

ANSI/J-STD-004 |

Benefits

PERFORMANCE

- Excellent solder joint strength

- Very good wetting on all surface finishes, including OSP

COST

- Reduced energy consumption

HSE

- Lead Free

- Free of CMR containing substances

Process Recommendation

SOLDER PASTE PREPARATION

Put the paste at room temperature for at least 4 hours prior to use.

DISPENSING GUIDELINE

Apply the paste in dots using a micro-dispenser, with needles having an inner diameter greater than 0.5 mm.

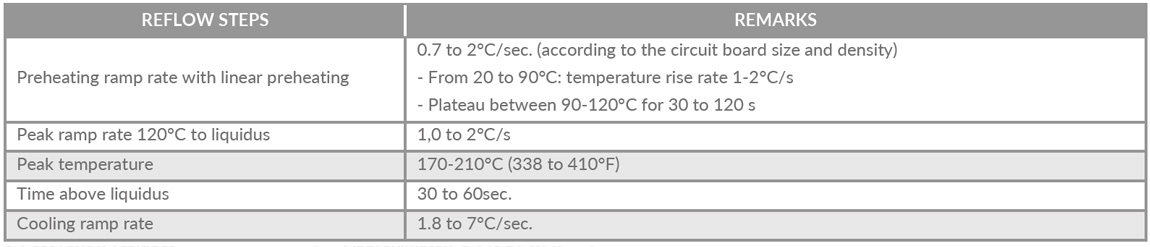

REFLOW GUIDELINE

Although this paste performs very well under air, a nitrogen atmosphere will even improve the wettability whereas achieving a larger reflow process window.

Linear preheating ramp rate is recommended; however high-density boards may require a soak zone during preheating to stabilize the temperature over the circuit board before peak reflow.