PROMOCLEAN OVEN 4

Best manual reflow oven cleaner

- Removal baked-on flux residues

- Manual cleaning

- Fast & effective cleaning

PROMOCLEAN OVEN 4

Is especially designed for manual cleaning of all types of baked-on flux residues left on reflow oven parts, conveyor fingers in wave soldering equipment and waves carriers.

Thanks to its excellent wettability and reactive substances it contributes to a fast maintenance process. Its medium alkaline pH allows an efficient cleaning without damaging sensitive metals or alloys.

It is a ready-to-use product that does not need to be diluted.

SPECIFICATIONS

| SPECIFICATIONS | VALUES | METHODS |

|---|---|---|

| Aspect | Yellow liquid | Visual |

| Density at 20°C (g/ml) | 0,97 ± 0,01 | BRY-MO-028 |

| pH of pure product | 11,3 ± 0,5 | BRY-MO-011 |

| pH at 1% | 10,1 ± 0,5 | BRY-MO-011 |

CHARACTERISTICS

| CHARACTERISTICS | VALUES |

|---|---|

| Flash point | None |

| Solubility in water | Totally soluble |

| Advised application temperature limits | Min 20°C / 68°F and Max 80°C / 176°F |

| VOC | 20,97 g/L (2%) |

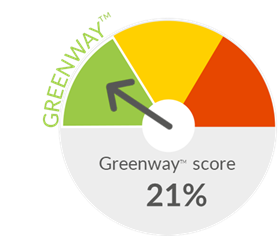

This is a product

MAIN CONTRIBUTORS WHICH REDUCE IMPACT:

HUMAN HEALTH & SAFETY

- Non-flammable, no flashpoint & no EUH risk phrases: 100% safe for storage and when used in equipment

- Non-toxic & Low corrosive impact

ENVIRONMENT PROTECTION & RESOURCES SAVINGS

- No GWP

- Very low VOC

- No environmental hazard: no H labelling regarding environment

Benefits

PERFORMANCE

- Removal of all types of baked-on flux residues

- Fast & efficient cleaning

- Easy to use

COST

- Low consumption because of the low evaporation rate

- Reduces substantially equipment downtime

HSE

- Non-toxic & no CMR substances

- Low environmental impact: No GWP, No ODP & Low VOC

- Non flammable / safe substitution to IPA & other flammable cleaners

Process recommendation

Promoclean Oven 4 is only suitable for manual use. As it is designed to release it reactive agents quickly, it has a very short bath-life when used in a cleaning equipment. We recommend Promoclean Disper 610 for cleaning in an immersion or spray equipment.

How to use?

STEP 1

spray or pour on the

surface to clean

surface to clean

STEP 2

let the cleaner react for

1-2 minutes

1-2 minutes

STEP 3

wipe clean with dry

paper or cloth

paper or cloth

- The cleaning time depends on the amount of residue and time between each maintenance. We recommend frequent cleaning for a more efficient cleaning process. Regular cleaning decreases the overall cleaning time, consumption of cleaning chemistry and expands the lifetime of your equipment.

- As the product is non-flammable, the product can be used on medium hot surfaces (maximum 80°C/176°F), reducing the downtime of your equipment.