Solder Flux Repair Solutions

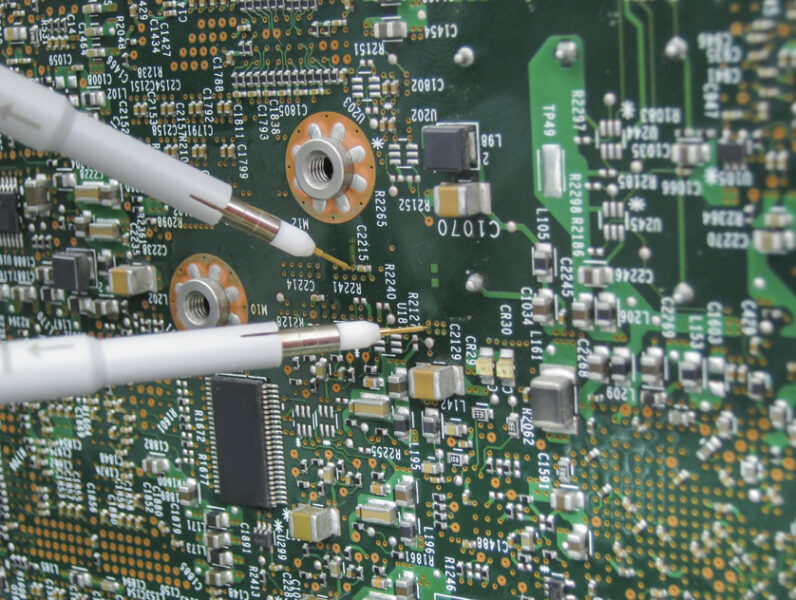

Our advanced solder flux repair solutions are designed to deliver precise, reliable solder repair performance with superior wetting, strong joint integrity, and consistent electrical connectivity—ideal for high-precision rework soldering and complex component repair applications.

Boost Precision and Reliability with Advanced Solder Flux Repair Solutions

Advanced solder flux repair solutions are essential in modern electronics rework processes, especially when working with fine-pitch and high-density packages like BGA and QFN. These solutions enable technicians to perform reliable, long-lasting repairs with high accuracy.

Tacky fluxes are widely used in precision solder repair due to their strong adhesion, which stabilizes components during the rework soldering process. This ensures proper alignment and prevents movement while solder is applied, which is critical in complex assemblies.

Both tacky and liquid solder flux formulations help clean oxidation, promote solder wetting, and enhance the electrical and mechanical quality of the joint. Selecting the right flux for each application improves rework yield and extends the service life of electronic assemblies.

Key Benefits of Solder Flux Repair Solutions:

- Ensures strong adhesion and precise component placement during rework

- Removes oxidation and promotes optimal solder wetting

- Supports high-performance repair of BGA, QFN, and SMD components

- Available in tacky and liquid formats for varied rework needs

INVENTEC offers high-performance solder flux repair solutions designed to improve rework efficiency, reliability, and long-term solder joint integrity.

See Other Repair Solutions Read FAQ

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Showing all 2 results

-

-

ECOFREC TF48

- No clean tacky flux

- Flip Chip, spheres soldering & components rework

- Excellent printing & high viscosity

Discover Our Halogen-Free No-Clean Tacky Flux for All Your Soldering Needs!

ECOFREC TF49

- Halogen free tacky flux

- Flip Chip & Rework soldering

- Low residue properties

Solder Flux

Rework & Repair Soldering Solutions

Frequently Asked Questions (FAQ)

What are solder flux repair solutions?

Solder flux repair solutions are specialized flux formulations designed to facilitate the rework and repair of electronic assemblies. They help remove oxidation, improve solder wetting, and ensure reliable solder joints during repair processes.

Why is solder flux important in rework and repair?

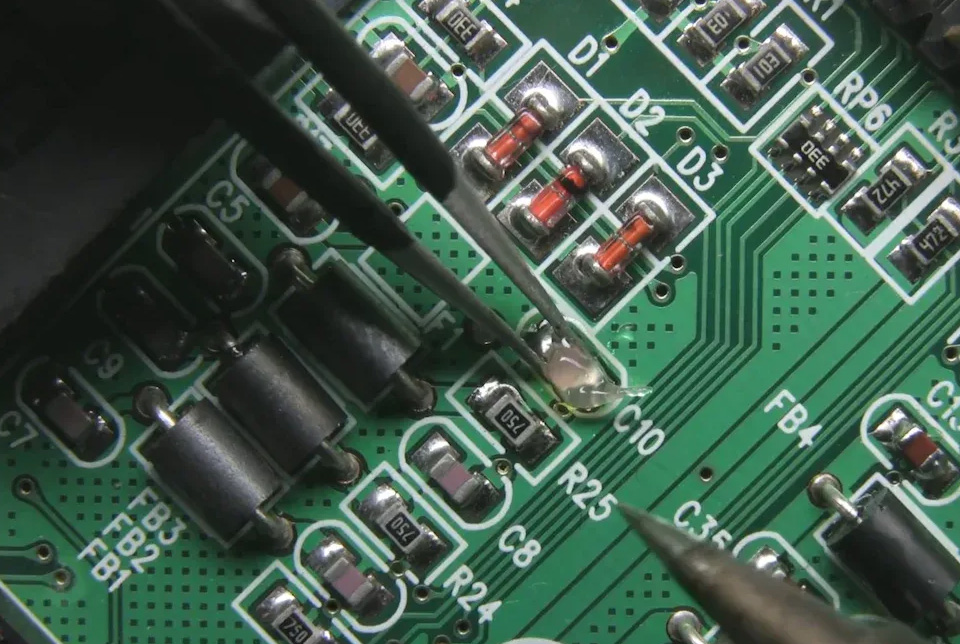

Flux is essential in rework to clean surfaces, activate metals, and promote wetting of solder. Proper flux application prevents defects like cold joints or bridging, ensuring durable and high-quality repairs.

What types of fluxes are used for solder repair?

Common flux types include rosin-based, water-soluble, no-clean, and tacky fluxes. The choice depends on the repair method, component sensitivity, and cleaning requirements.

How do no-clean solder flux repair solutions benefit rework?

No-clean fluxes leave minimal, non-corrosive residues after soldering, reducing or eliminating the need for cleaning. This speeds up repair cycles and lowers the risk of damage from cleaning processes.

Can solder flux repair solutions be used on lead-free solder alloys?

Yes. Modern repair fluxes from INVENTEC are formulated to be fully compatible with lead-free alloys like SAC305, providing excellent wetting and solderability during lead-free rework.

What precautions should be taken when using flux in repair?

Proper flux application is critical—over-application can cause bridging, while under-application may lead to poor wetting. Also, ensure flux residues are compatible with cleaning procedures or safe to leave on the assembly.

How does tacky flux assist in solder repair?

Tacky fluxes provide adhesion to components during rework, preventing movement and enabling precise placement while ensuring optimal solder joint formation.

Are solder flux repair solutions compatible with automated rework stations?

Yes. INVENTEC’s flux repair solutions are designed to be compatible with manual and automated rework processes, including soldering irons, hot air stations, and selective soldering equipment.

What role does flux play in minimizing voids during repair soldering?

High-quality flux promotes proper outgassing and wetting, reducing the formation of voids in solder joints, which enhances mechanical strength and thermal performance after repair.

Does INVENTEC offer solder flux products specifically for repair applications?

Yes, INVENTEC Performance Chemicals provides a range of solder flux repair solutions tailored for rework and repair needs, optimized for performance, residue management, and ease of use in industrial settings.

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning & coating trials

Do you need cleaning or coating after soldering? We provide FREE-OF-CHARGE cleaning or coating trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. It is also possible to attend trials in person.