Low Temperature Solder Paste Solutions

Advancements in low temperature solder paste solutions are enabling more energy-efficient, reliable, and design-flexible electronics manufacturing by reducing reflow temperatures, minimizing PCB warpage, and supporting sustainable production practices.

Optimizing Reflow Processes with Low Temperature Solder Paste Solutions

Low temperature solder paste is transforming SMT assembly by offering a more energy-efficient, cost-effective, and environmentally responsible alternative to traditional high-temperature soldering processes.

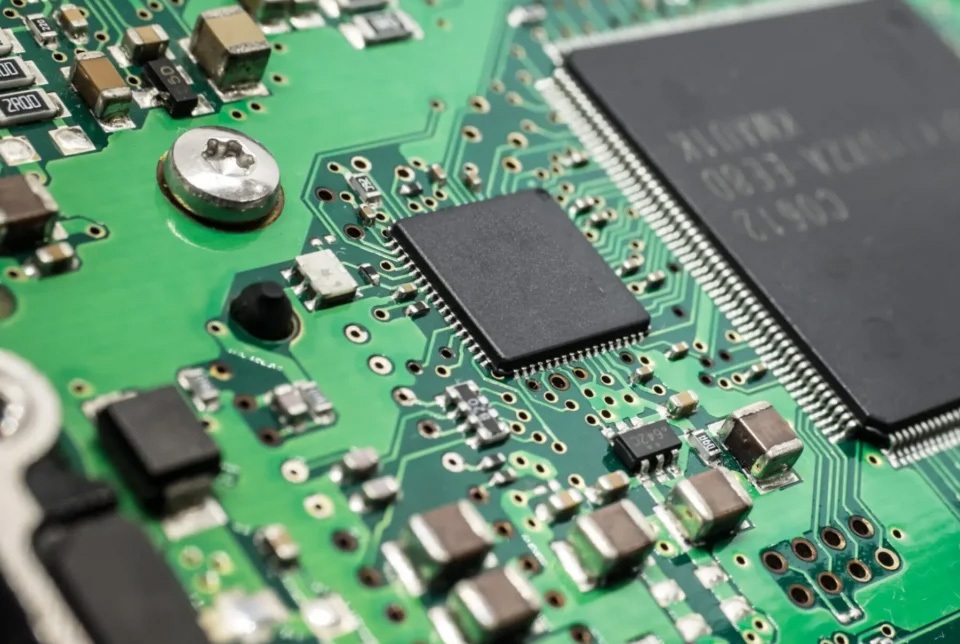

INVENTEC’s low melt solder pastes allow for reliable soldering at significantly reduced reflow temperatures—ideal for heat-sensitive components and complex multi-layer PCBs. These formulations minimize thermal stress, reduce PCB warping, and support compact design layouts through simplified process steps like single-pass reflow.

In addition to technical performance, these low temp solder paste solutions help manufacturers lower their carbon footprint by cutting energy consumption and CO₂ emissions—meeting today’s sustainability goals without compromising on solder joint quality or reliability.

Key Benefits of Low Temperature Solder Pastes:

- Lower reflow temperatures reduce stress on components and substrates

- Improved process flexibility and compatibility with sensitive materials

- Energy savings and lower operational costs

- Ideal for compact, high-density, or multi-layer PCB designs

INVENTEC’s low temperature solder pastes are designed to meet modern demands for greener, more efficient, and thermally optimized electronics manufacturing.

See Other SMT Solder Paste Processes Read FAQ

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Showing the single result

-

ECOREL FREE LT 140-18

- Sn42Bi57.6Ag0.4 lead free solder paste

- Low temperature SMT printing process

- Halogen free & low voiding

Discover our halogen free, low voiding and low temperature solder paste!

ECOREL FREE LT 140-18

- Sn42Bi57.6Ag0.4 lead free solder paste

- Low temperature SMT printing process

- Halogen free & low voiding

Low Temperature

Solder Paste Solutions

Frequently Asked Questions (FAQ)

What are low temperature solder paste solutions?

Low temperature solder pastes are specially formulated alloys designed to melt at temperatures significantly lower than traditional solder pastes, typically below 200°C. These pastes help reduce thermal stress on sensitive components and substrates during the soldering process.

Why use low temperature solder pastes in industrial applications?

Low temperature solder pastes minimize heat exposure, protecting temperature-sensitive components like plastics, LEDs, and certain semiconductors. They also enable soldering on substrates that can’t withstand high temperatures, improving overall assembly reliability.

What are common alloy compositions in low temperature solder pastes?

Typical alloys include bismuth-tin (Sn-Bi), indium-based, or tin-silver-bismuth blends, which melt at temperatures ranging from 138°C to 190°C. These alloys provide good wetting and mechanical strength suitable for various industrial uses.

How do low temperature solder pastes affect reflow profiles?

Reflow profiles for low temperature pastes require lower peak temperatures and carefully controlled ramp rates to avoid premature melting or poor joint formation. Always follow the solder paste manufacturer’s recommended profiles for optimal results.

Are low temperature solder pastes compatible with standard SMT equipment?

Yes. Low temperature solder pastes can be used with existing stencil printers, jet printers, and reflow ovens, although reflow oven settings must be adjusted for the lower melting points. INVENTEC Performance Chemicals offers low temperature formulations optimized for standard industrial processes.

What industries benefit most from low temperature solder paste solutions?

Industries such as consumer electronics, medical devices, automotive, and LED manufacturing benefit from low temperature solder pastes, especially when assembling heat-sensitive components or substrates.

Do low temperature solder pastes provide reliable solder joints?

When properly applied and reflowed, low temperature solder pastes form strong, durable solder joints with good mechanical and electrical properties, suitable for most industrial applications requiring reduced thermal exposure.

Can low temperature solder pastes be lead-free?

Yes, many low temperature solder pastes are formulated as lead-free alloys compliant with RoHS standards. INVENTEC Performance Chemicals offers lead-free low temperature solder pastes that balance environmental compliance with performance.

How should I store low temperature solder pastes?

Low temperature solder pastes should be stored refrigerated (typically 0-10°C) to maintain their chemical properties and prevent premature curing. Proper handling ensures consistent printability and solder joint quality.

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning & coating trials

Do you need cleaning or coating after soldering? We provide FREE-OF-CHARGE cleaning or coating trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. It is also possible to attend trials in person.