Low & No-Silver Solder Paste Solutions

Our specialized range of no-silver and low-silver solder paste solutions is engineered to deliver cost-effective performance without compromising on reliability, wetting, or thermal stability ideal for high-volume production and environmentally conscious electronic assembly applications.

Smarter Soldering with Low-Silver & No-Silver Solder Pastes

INVENTEC’s low-silver and no-silver solder paste solutions help manufacturers reduce material costs while enhancing mechanical durability and corrosion resistance in modern SMT processes.

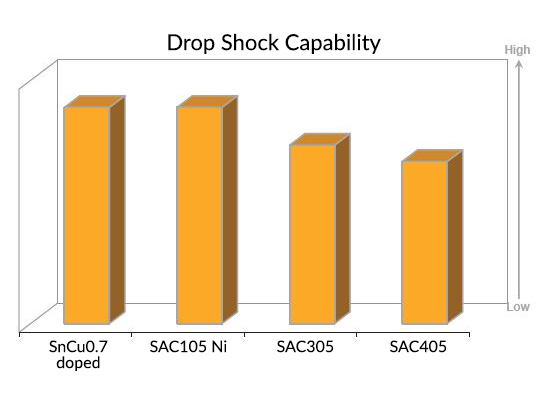

Low-silver pastes are ideal for cost-sensitive, high-reliability applications like handheld devices and automotive electronics, where drop shock resistance is critical. These alloys deliver strong performance without compromising on solder joint integrity.

No-silver pastes offer an even more economical option, eliminating silver content entirely while maintaining excellent wetting, stability, and long-term reliability—particularly when paired with our proven ECOREL™ chemistry.

Key Advantages of Low- and No-Silver Solder Pastes:

- Reduced raw material costs without sacrificing solder joint quality

- Enhanced drop shock resistance for mobile and automotive applications

- Minimized corrosion risk with silver-free formulations

- Optimized for high-volume SMT processes with ECOREL™ technology

INVENTEC’s ECOREL™ low- and no-silver solder pastes deliver cost-effective, high-reliability solutions for modern SMT assembly challenges.

See Other SMT Solder Paste Processes Read FAQ

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Showing the single result

Discover our low-silver SAC105 solder paste for high-volume electronics!

ECOREL FREE 105-16

- Low silver SAC105 lead free alloy solder paste

- No clean SMT printing process

- Robust Assembly Process

Low & No-Silver

Solder Paste Solutions

Frequently Asked Questions (FAQ)

What are low and no-silver solder paste solutions?

Low and no-silver solder pastes are specialized formulations designed to minimize or eliminate silver content in solder alloys. These pastes aim to reduce material costs and mitigate supply chain risks while maintaining strong mechanical and electrical properties suitable for various industrial soldering applications.

Why consider using low or no-silver solder pastes?

Silver is an expensive and sometimes scarce commodity. Using low or no-silver solder pastes helps reduce overall material costs and dependency on silver supply. Additionally, these pastes can offer comparable reliability and thermal performance when properly formulated and applied.

What are common alloy compositions for low and no-silver solder pastes?

Common low-silver alloys include SAC105 (Sn-1.0Ag-0.5Cu) or SAC0307, which reduce silver content compared to standard SAC305. No-silver alloys typically use tin-copper (Sn-Cu) or tin-bismuth (Sn-Bi) combinations designed for specific applications.

How does reducing silver affect solder joint reliability?

While silver enhances mechanical strength and thermal fatigue resistance, advances in solder paste chemistry and alloy design allow low and no-silver pastes to meet demanding reliability requirements. Testing under IPC standards ensures these materials perform well in automotive, aerospace, and consumer electronics.

Are low and no-silver solder pastes compatible with existing industrial soldering equipment?

Yes. Low and no-silver solder pastes are formulated to work with standard SMT stencil printers, jet printers, and dispensing systems. INVENTEC Performance Chemicals offers compatible solder paste solutions tailored for these applications without requiring equipment modifications.

What are typical applications for low and no-silver solder pastes?

These pastes are widely used in consumer electronics, automotive modules, LED manufacturing, and industrial control systems where cost-efficiency and reliable solder joints are critical. They are also favored in high-volume production to optimize material costs.

How do low and no-silver solder pastes affect reflow profiles?

Reflow profiles may require slight adjustments due to different melting points and wetting characteristics compared to traditional SAC305. Following manufacturer guidelines and proper process validation ensures optimal solder joint quality and process stability.

Does INVENTEC offer low and no-silver solder paste formulations?

Yes. INVENTEC Performance Chemicals provides advanced low and no-silver solder paste solutions designed to balance cost, performance, and environmental compliance. Their products support a wide range of industrial soldering needs with reliable process consistency.

Are low and no-silver solder pastes RoHS compliant?

Most low and no-silver solder pastes from INVENTEC and other reputable suppliers are fully RoHS and REACH compliant, meeting international regulations for hazardous substance restrictions in electronics manufacturing.

What testing should be done when switching to low or no-silver solder paste?

It is important to conduct solder joint reliability testing, such as thermal cycling, shear strength, and wetting balance. Process capability studies and reflow profile optimization are also recommended to ensure the new paste meets your production and quality standards.

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning & coating trials

Do you need cleaning or coating after soldering? We provide FREE-OF-CHARGE cleaning or coating trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. It is also possible to attend trials in person.