PROMOCLEAN TP 1115

Removal of Polishing Pastes & Oils

- Removing polishing pastes & oils on metal parts

- Aqueous immersion process with ultrasonics

- Finishing & rinsing step with hard water possible

PROMOCLEAN TP 1115

Is especially designed for removal of polishing pastes, hydrocarbon & water-soluble oils in an aqueous immersion process with ultrasonics.

Thanks to its medium pH, it doesn`t damage ferrous and non-ferrous alloys like Inox, Titanium & Copper, Aluminium & Brass. Likewise, it can be used on precious metals such as gold and silver.

It’s a concentrated product which is used diluted with DI or tap water and has a very long bath life even at low concentration.

PROMOCLEAN TP 1115 is qualified and used by several actors in the luxury watch, jewellery & medical parts manufacturing.

Specifications

| Specifications | Values | Methods |

|---|---|---|

| Aspect | Yellow | Visual |

| Density at 20°C (g/ml) | 1,08 ± 0,01 | BRY-MO-028 |

| pH of pure product | 11,5 ± 0,5 | BRY-MO-011 |

| pH at 1% | 10,3 ± 0,5 | BRY-MO-011 |

Characteristics

| Characteristics | Values |

|---|---|

| Solubility in water | Totally soluble |

| Surface tension at 1% | 37 Dynes / cm² |

| Refractive index at 20°C | 1,38 |

Request a sample

for "PROMOCLEAN TP 1115"

This is a product

MAIN CONTRIBUTORS WHICH REDUCE IMPACT:

HUMAN HEALTH & SAFETY

- Non-flammable, no flashpoint & no EUH risk phrases: 100% safe for storage and when used in equipment

- Non-toxic

ENVIRONMENT PROTECTION & RESOURCES SAVINGS

- Low environmental impact: no H labelling regarding environment

- No GWP & Very low VOC (<25% of VOC compound)

- Made partially with renewable raw materials

Benefits

Performance

- Compatibility with a wide range of metals, including sensitive ones

- Does not leave spots or residues

- Excellent chelating action for rinsing step

Cost

- High cleaning power even at low concentration

- Very long bath-life

HSE

- Non-toxic & no CMR substances

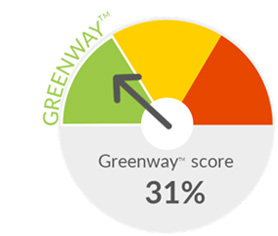

- Low environmental impact: GREENWAY product

- Non-flammable & will not cause an exothermic reaction in the cleaning tank

Process examples

The most suitable process will depend on factors such as operating conditions, equipment, desired cleaning and the nature of the contaminants. Our team is therefore there to advise you.

Water-based oil removal

PROMOCLEAN TP 1115

Conc: 2-5% for degreasing

Conc: 1-2% for final cleaning

Temp: 50-60°C / 122-140°F

US: yes

Time: 2-5 min

CLEANING

DI WATER

Temp: 20-30°C/68-86°F

US: optional

Time: 2-5 min

RINSING

HOT AIR or VACUUM or DRYING SOLVENT

Time: 5-20 min

DRYING

- For cleaning of hard to remove polishing pastes, other products from the PROMOCLEAN range could be used in combination with PROMOCLEAN TP 1115 in order to improve process efficiency.

- A dedicated PCA Kit to monitor the bath status and compatibility report with different materials are available on request.

- It’s key to determine the maximum time materials can be exposed to the cleaning chemical. Although our cleaning products will not damage materials they are designed for under normal conditions, prolonged exposure may.